Choosing the Best Defoamers for Your Manufacturing Line

Choosing the Best Defoamers for Your Manufacturing Line

Blog Article

How Defoamers Improve Effectiveness in Manufacturing and Production

Comprehending Defoamers

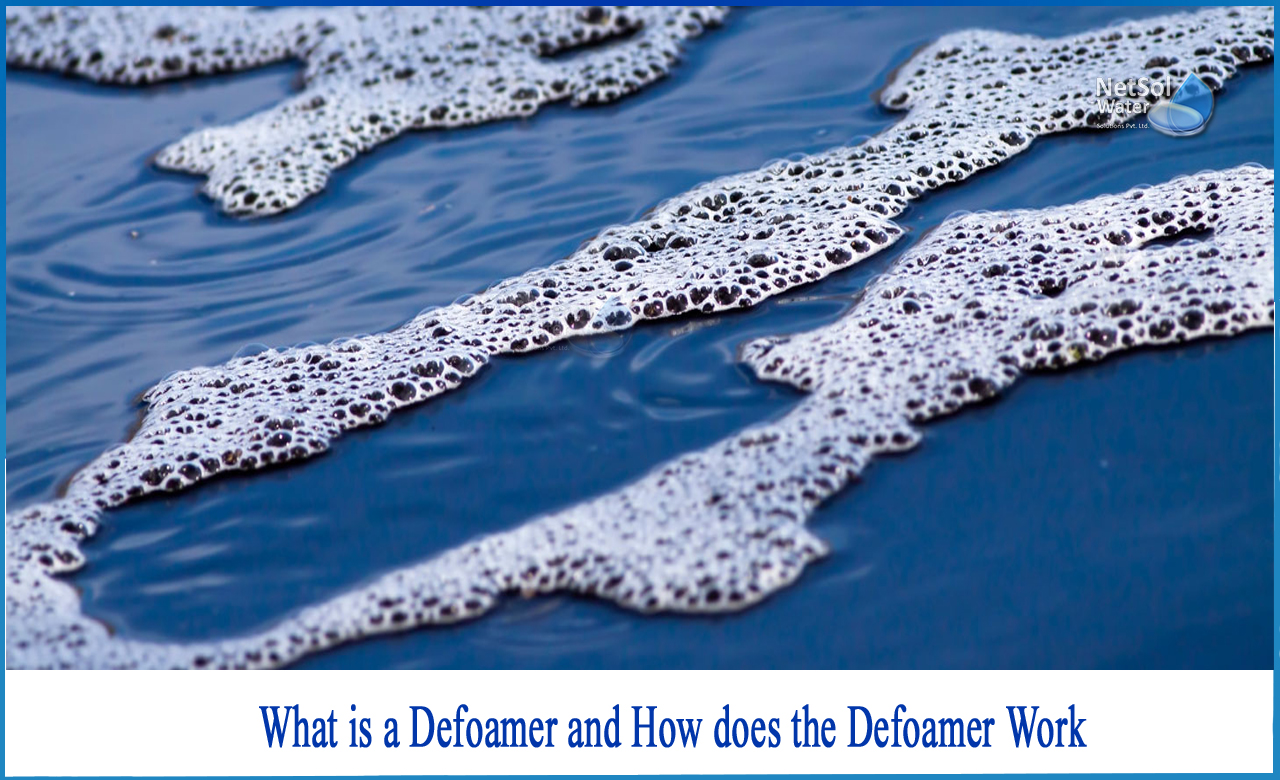

Defoamers play an essential function in various manufacturing procedures by effectively combating the development of foam, which can interrupt operations and affect product quality. Foam can arise in numerous contexts, such as throughout mixing, heating, or chain reactions, possibly causing inadequacies and disparities in items. The mechanism by which defoamers operate generally includes reducing the surface area stress of the liquid, enabling bubbles to coalesce and climb to the surface a lot more conveniently, where they can after that break.

Reliable defoamers not just reduce foam development yet likewise preserve compatibility with the item, making certain that there are no damaging results on the last result. Recognizing the homes and features of defoamers is essential for manufacturers aiming to maximize their procedures, boost efficiency, and maintain the honesty of their products (defoamers).

Secret Benefits of Defoamers

Using defoamers in manufacturing processes offers a variety of significant advantages that boost functional efficiency and product high quality. One of the key benefits is the decrease of foam formation during production, which can block equipment and interfere with operations. By reducing foam, defoamers guarantee smoother operations, causing decreased downtime and maintenance expenses.

Additionally, defoamers improve item uniformity by stopping air entrapment, which can jeopardize the honesty of the end product. This is especially vital in industries where aesthetic look and structure are crucial, such as in paints, coverings, and foodstuff. Improved product top quality not only satisfies customer assumptions yet additionally strengthens brand reputation.

Furthermore, defoamers can aid in enhancing resource use. By improving the performance of basic material application, they add to set you back financial savings and lowered waste, aligning with sustainability objectives. The application of defoamers can lead to shorter processing times, allowing manufacturers to raise production capacity without substantial capital financial investment.

Applications in Numerous Industries

In manufacturing procedures throughout various sectors, the application of defoamers plays a critical function in improving effectiveness and product high quality. These chemical additives are utilized in markets such as food and drink, pharmaceuticals, and fabrics to minimize foam-related difficulties.

In the food and beverage market, defoamers are necessary throughout the fermentation process, protecting against lathering that can disrupt production and spoil the item's integrity. In a similar way, in the pharmaceutical industry, defoamers are used in the formula of liquid medicines, ensuring harmony and stability while lessening waste.

Textile more info here production likewise benefits from defoamers, as they are made use of in dyeing and completing procedures to advertise also distribution of dyes and chemicals. This application not just enhances the end product's look however likewise reduces the amount of water and power eaten during production.

Additionally, in the paper and pulp industry, defoamers assist maintain process performance by decreasing foam that can prevent machinery efficiency. Generally, the diverse applications of defoamers throughout these markets underscore their importance in enhancing manufacturing processes and delivering high-grade products.

Picking the Right Defoamer

Picking a proper defoamer is important for making the most of efficiency and top quality in making procedures. The selection of defoamer depends upon numerous elements, including the particular application, the kind of foam being produced, and the formulation of the product being produced.

First of all, consider the chemical compatibility of the defoamer with various other active ingredients in your solution. A defoamer that connects negatively with other elements can detrimentally influence item top quality. In addition, the temperature and pH range throughout handling are important; some defoamers carry out ideally under specific conditions while coming to be ineffective in others.

Second of all, examine the defoamer's performance qualities, such as its ability to quickly reduce foam and its perseverance throughout production. It is necessary to select a product that not only removes foam swiftly yet look what i found also keeps its efficiency in time.

Last but not least, think about environmental and regulative variables, particularly if your manufacturing process undergoes rigorous compliance criteria. Picking a biodegradable or low-toxicity defoamer can help meet sustainability goals while making sure functional effectiveness. By attentively examining these criteria, manufacturers can make enlightened choices that enhance productivity and product stability.

Ideal Practices for Implementation

Successful implementation of defoamers in producing procedures calls for careful planning and adherence to best methods. Picking the ideal defoamer, as formerly talked about, is essential; guarantee it is compatible with the products included and attends to the determined lathering concerns effectively.

Next, keep clear communication with all stakeholders, consisting of operators and quality control teams. Training sessions can assist ensure that everybody comprehends the dosing treatments, potential effects on item high quality, and safety and security factors to consider. Carrying out a trial stage can likewise be advantageous; screen performance closely to gauge efficiency and make essential changes.

Additionally, routine testing and tracking of foam degrees can give useful understandings right into the defoamer's performance in time. Adjusting dosages in feedback to modifications in manufacturing variables will assist preserve optimal effectiveness - defoamers. Lastly, documenting all processes and results advertises constant enhancement, enabling fine-tuning of defoamer usage and boosting total productivity in making operations.

Verdict

In summary, defoamers play an essential function in improving performance within manufacturing and production processes. By lessening foam formation and facilitating bubble coalescence, defoamers add to boosted product top quality, consistency, and operational effectiveness. Their application across various industries underscores their convenience and importance in enhancing resource use and minimizing processing times. Eventually, the tactical implementation of defoamers enables manufacturers to boost manufacturing capability properly, thereby fulfilling client assumptions and attaining cost financial savings.

The benefits prolong to product quality and price savings, as defoamers assist enhance processes.Defoamers play a critical duty in different manufacturing procedures by effectively combating the development of foam, which can interfere with procedures and impact product high quality. Recognizing the buildings and functions of defoamers is crucial for makers intending have a peek at this site to optimize their procedures, improve productivity, and preserve the stability of their products.

Utilizing defoamers in manufacturing processes provides a variety of substantial advantages that improve functional performance and product high quality.Furthermore, defoamers enhance item uniformity by avoiding air entrapment, which can endanger the stability of the final item.

Report this page